nemo

internal inspection robot

of wind turbine blades

nemo is the perfect solution for the internal inspection of wind turbine blades.

Discover nemo

Our small, remotely controlled robot has the ability to access up to 75% of the blade length in internal shovel sections where human access is impossible.

Its high-resolution cameras, combined with the illumination system, provide clear images of the detected defects.

The system is equipped with software specifically developed to facilitate inspection tasks and to make the use of the equipment simple and intuitive from the very first moment.

The benefits of incorporating nemo into your company

Minimum size

Nemo allows to access places where an operator would not be able to. It allows real-time visualization of the defects found with the built-in high-performance cameras.

Minimizes human risk

Completely eliminates the risk of operators working in confined spaces.

Cost

reduction

The internal inspection allows early detection of damages inside the blades, and to act before catastrophic failures occur in the blade structure.

nemo

wind blades inspection

Two versions tailored to your needs, offering countless combinations.

Common features

Hardware & Software

- Base station: Microsoft Surface PRO 13''

- OS: Windows 11 Pro

- Video resolution: Full HD 1080p

- GCS battery life: Up to 4 hours

- Main control software: Nemo Rover App

Key Specifications

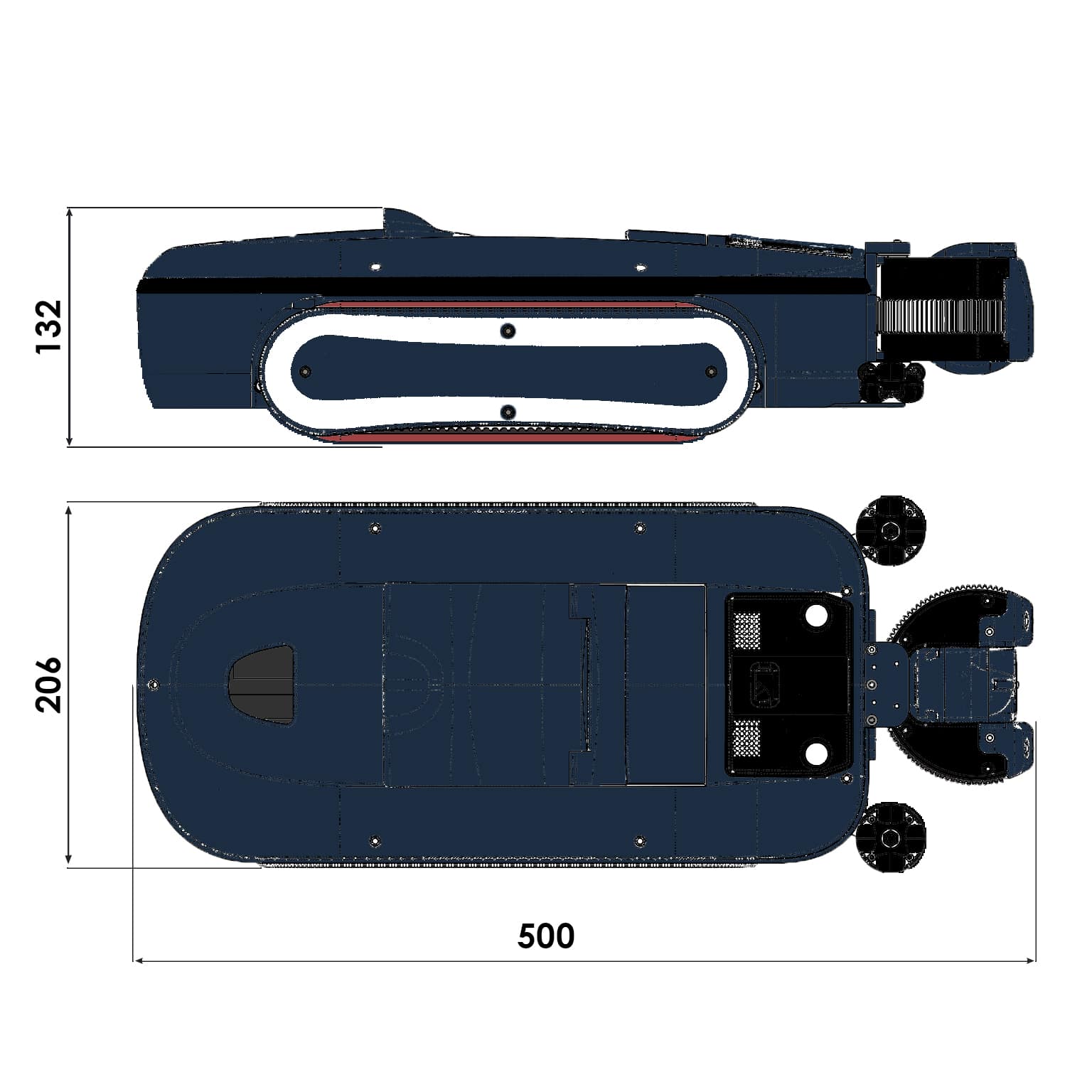

- Size: 500 x 206 x 122 mm (LxWxH)

- Weight: 4.6 kg

- Maximum speed: 0,6 m/s

- Climbing angle: 30º

- Processor: Nvidia Jetson

- Gimbal Yaw range: ±90º

- Gimbal Tilt range: -25º to +90º

- Sensor: Sony Autofocus

- Image Resolution: 4056 x 3040

Two different versions

nemo full vision V3

Nemo Full Vision is equipped with a high-precision gimbal and extensive range of motion. Nemo provides reliable internal inspections covering up to 80% of the blade surface. Its advanced manoeuvrability ensures accurate diagnostics even in the most challenging conditions, maximizing efficiency and reducing downtime.

- Power source: Li-Ion battery

- Communications range: up to 75 m

- Operation time: up to 4 hours per battery

- Case dimensions: 600×400×278 mm (L×W×H)

- Transport case weight: 13 kg

nemo full vision tethered V3

Nemo Tethered delivers uninterrupted performance thanks to its wired power and Ethernet connection.

There are no time limits. No signal drops.

This ultra-stable link ensures smooth, reliable operation—even in the most demanding inspection environments.

Perfect for critical tasks where consistency and precision matter most.

- Power source: Tethered power supply

- Communications range: 50-100 m (configurable)

- Operation time: Continuous/unlimited

- Case dimensions: 600 x 400 x 278 mm (LxWxH)

- Transport case weight: 25 Kg

Accessories

Several nemo configuration options are available to further enhance the equipment’s capabilities.

These include a range extender that allows you to reach up to 75 meters with a secure connection, and a cable meter system that lets you know Nemo’s position at all times.

Cable Counter

A precision digital system designed to provide an accurate count of almost any type of cable. We can also customize the design to fit your cable’s diameter.

Battery 6,7Ah

Nemo’s conventional battery, with a 4-hour runtime, is perfect given its small size and flexible usage.

Battery 17Ah

Our largest battery provides an uninterrupted runtime of 8 hours.

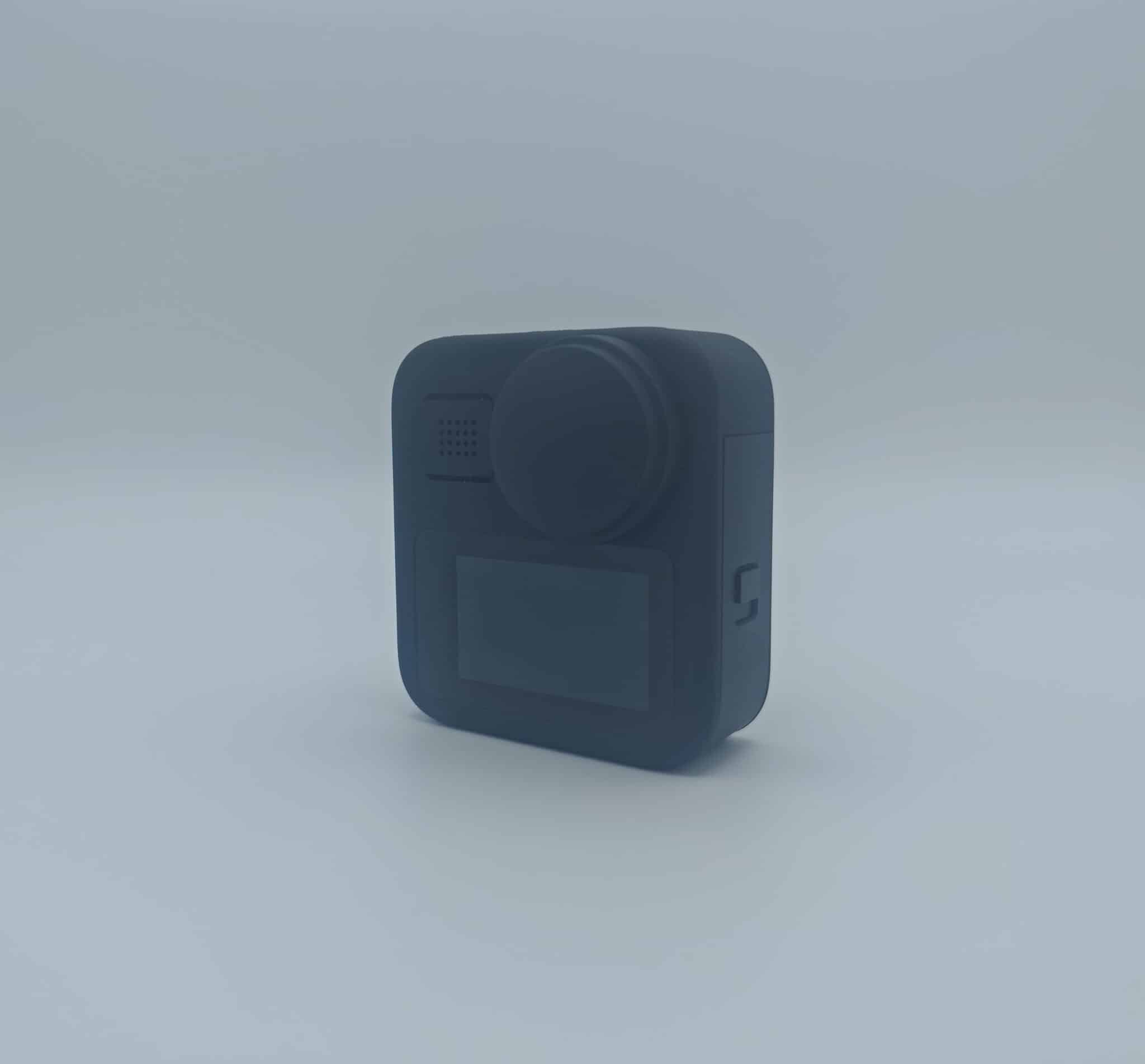

360º Camera

With our 360º camera, you get a complete view of the entire blade surface at the end of the inspection.

Tether module

Connects the nemo by cable to the GCS with the anchor module, making it independent of the batteries and providing a secure connection throughout the inspection.

Range Extender

Thanks to our range extender, the connection remains stable and secure up to 75 meters inside the blades.

nemo full vision

Unrestricted precision inspection

Our FULL VISION model redefines the limits of inspection. Thanks to its high-precision gimbal, capable of movements of -25º +90º in TILT and -90º +90º in YAW, the NEMO FULL VISION captures detailed orthogonal images of the upper and lateral areas of the blade, revealing the exact magnitude of any damage.

- Accurate Viewing: The integrated marker laser clearly indicates the direction of the camera, making it easy to identify areas of interest.

- Optimized lighting: The improved lighting system ensures sharp images in any condition.

- Versatility: Allows you to integrate measurement sensors to obtain exact dimensions of the interior of the blade and generate detailed reports.

Request info of our nemo product