Specialists in inspection and repair solutions for wind turbine blades

We extend the operating life of your blades and reduce O&M costs.

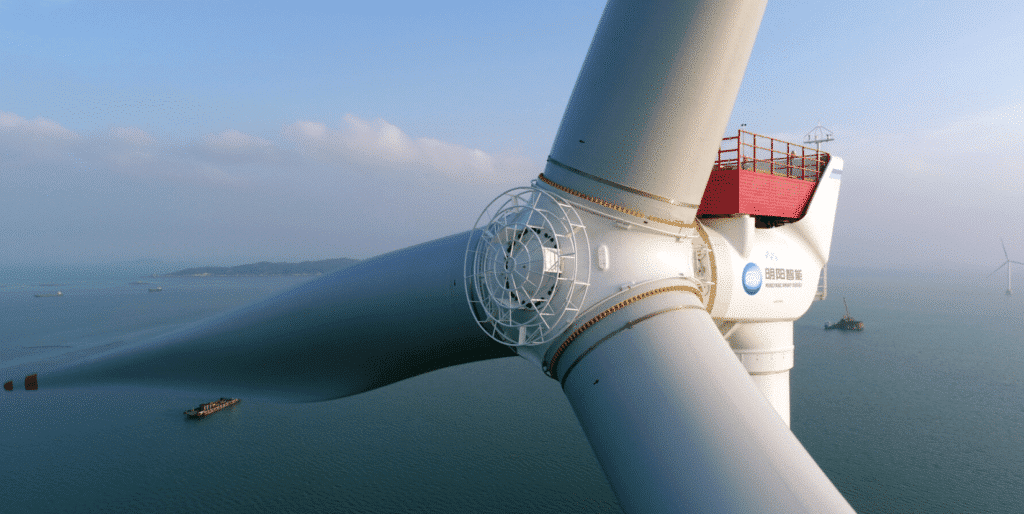

Robotic systems for inspection, detection and repair of wind turbine blades

WINDBOTIX combines more than 15 years of experience in blade repair and maintenance, together with an engineering team specialized in robot development, to develop innovative and efficient solutions to extend the life of your assets and optimize blade maintenance.

Our robots are designed to optimize inspection and repair work. Our main objectives in the maintenance of shovels, are reduce costs y eliminate risk to for operators.

Robotic systems for inspection, detection and repair of wind turbine blades

WINDBOTIX combines more than 15 years of experience in blade repair and maintenance, together with an engineering team specialized in robot development, to develop innovative and efficient solutions to extend the life of your assets and optimize blade maintenance.

Our robots are designed to optimize inspection and repair work. Our main objectives in the maintenance of shovels, are reduce costs y eliminate risk to for operators.

windbotix

How Windbotix can help you

Efficiency

The functional efficiency and service longevity of wind blades.

Security

Improving the safety and extending the service life of wind blades

Costs

Reduced maintenance and repair costs in the long term

Accuracy

Minimization of downtime and production losses in wind farms

windbotix

Services Inspection and Repair of wind blades

Want to learn more about our products and services?

Windbotix Products

nemo FULL VISION

nemo is the perfect solution for the internal inspection of wind turbine blades.

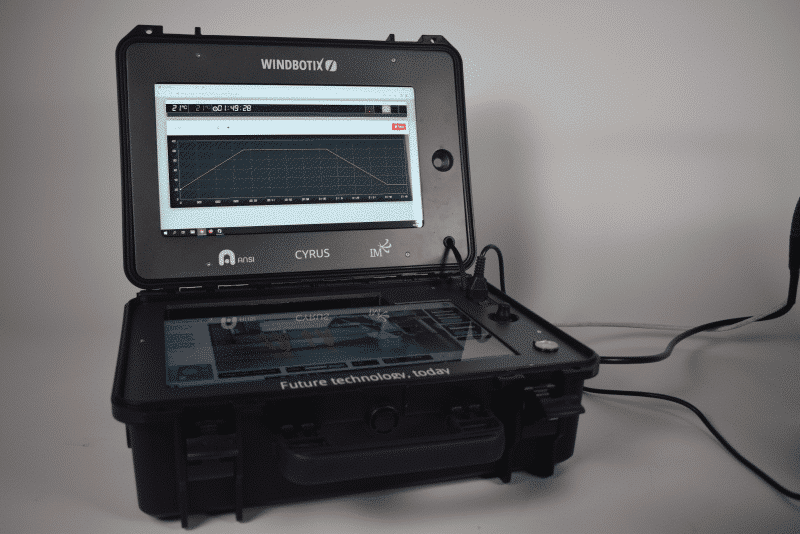

Cyrus

The big brother of nemo, the perfect tool for the internal repair of wind turbine blades.

Payload LPS

Coming Soon...