Identification and reparation of internal damages

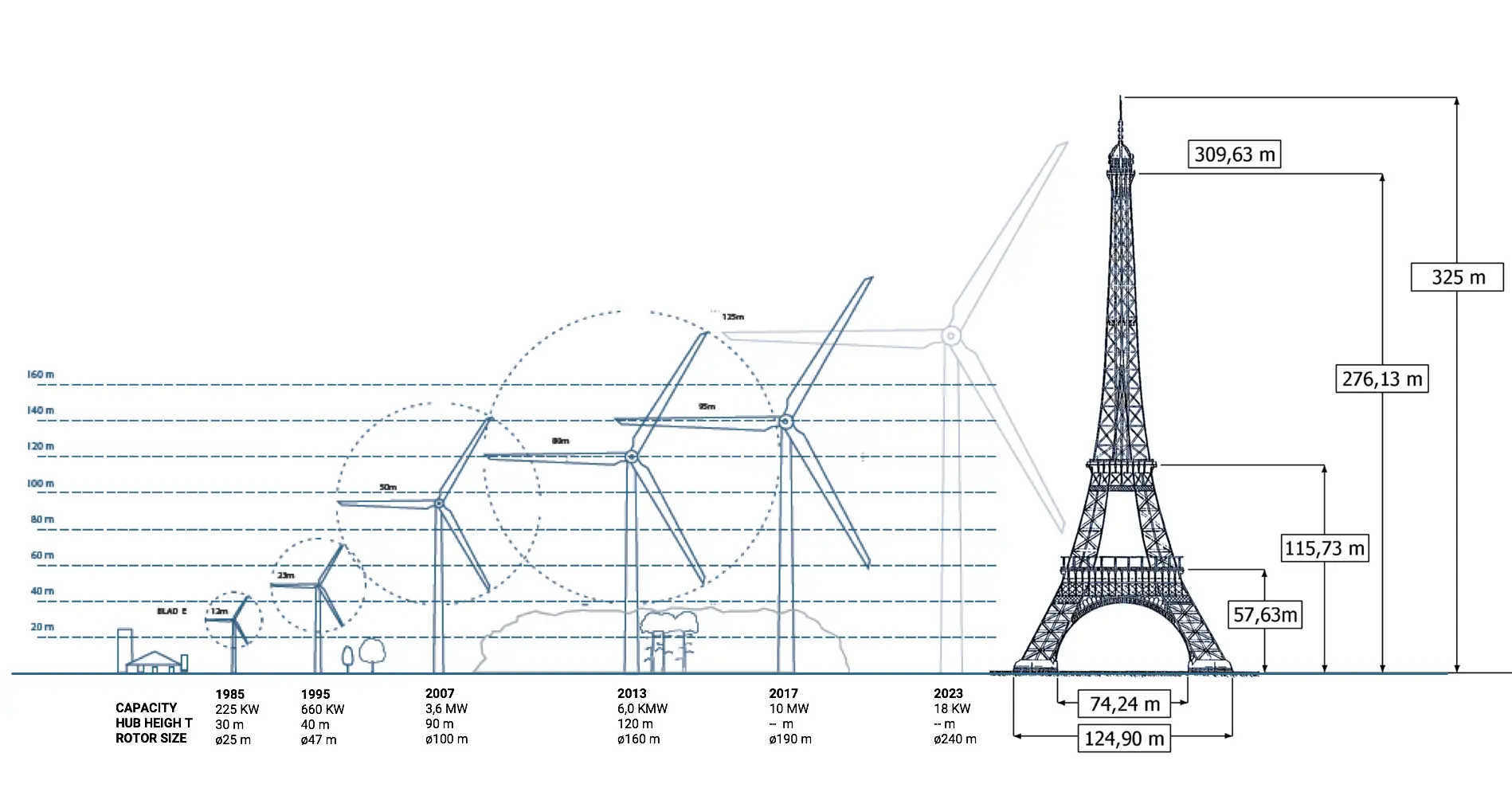

The growth rate of wind market

The installation of wind turbines in the world has had a high rate in recent years. According to statistics published by WWEA today, the world market for wind turbines reached another record in 2021 with wind turbines with a total capacity of 97,5 Gigawatt installed around the globe, after 92,7 Gigawatt in 2020. The overall capacity of all wind turbines worldwide has now exceeded 840 Gigawatt, enough to provide more than 7% of the global power demand. This equals a growth rate of 13%, compared to 14% one year earlier and 10% in 2019.

The challenge of performing inspection and maintenance tasks on blades

The blades of a wind turbine are the largest one-piece composite structures built in the world, even larger than the wings of any aircraft. They undergo more than one billion load cycles during their operative life, thus making periodic inspection and maintenance essential to keep wind turbines in service. Current inspection methods have a limited ability to detect structural damage early, which is crucial to avoid extremely costly repairs, or to avoid catastrophic failures, and to be able to repair them in order to extend the life of a blade. With current repair technologies it is possible to clean/sand and repair cracks situated on 1/3 of the blade, made by technicians accessing a confined space and unsanitary environment. It is not possible to repair cracks in the other 2/3 of the blade, and these can spread further and could potentially generate a catastrophic failure. If cracks are detected before a structural failure, the blade would be discarded and replaced. In addition, the methods and technologies currently available for internal inspection and repair of the blades require long downtimes of the wind turbine, with the consequent economic loss for the operating company. They are jobs with a high cost, and involve exposing operators to work at height, in confined spaces and unsanitary environments.

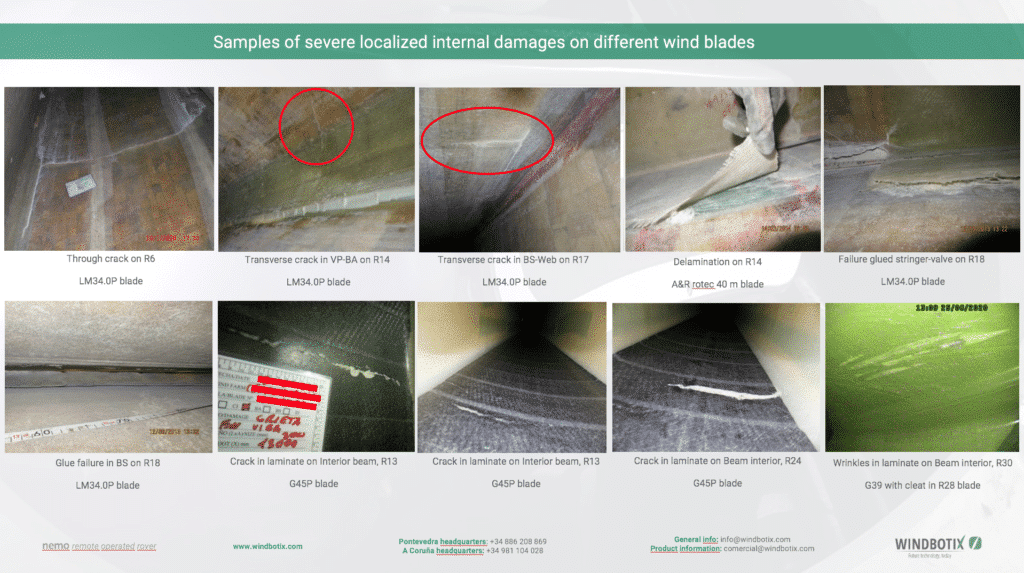

What kind of damages can be repaired with CYRUS robot

Technologies developed by WINDBOTIX are a game-changer in the scenario of internal repairs of wind blades. Our robot NEMO allows to inspect and detect internal cracks and structural damage along the structural beam at an early stage, and our robot CYRUS allows to repair internally blades along their critical areas, avoiding the access of operators to work inside confined space and harmful environment.

Using these robotic technologies, we are able to make repetitive and reliable repair methods, capable to work in very small size, milling process, placing patch and curing process under controlled conditions.

Below you can see real cases of inspection with a NEMO robot inside the beam, detecting structural cracks at different locations, as you can see:

These types of cracks must be repaired as soon as possible, so as not to compromise the operation of the machine. The usual procedure is by removing layers by sanitizing by roughing/sanding, replacing layers by manual rolling and vacuum compaction and curing of laminate by heating blankets.

Several cases of real inspections and repairs have been analyzed, where the use of a repair robot would avoid discarding the blade, in addition to avoiding exposing technicians to harmful environments.

With conventional repair technologies it is only possible to clean and repair internally cracks up to Z15 m, but CYRUS allows to repair blade till Z30 m ( 75% of a LM43-8).